Scaffolding Systems Across the Globe

A scaffolding system is a temporary structure designed to support workers and materials during the construction, maintenance, or repair of buildings and other structures. It allows safe access to heights and hard-to-reach areas that would otherwise be inaccessible. These systems vary widely by region, influenced by local materials, labour costs, regulations, and construction practices. Below is an overview of the main scaffolding types and their typical regional usage:

Asia-Pacific

Bamboo Scaffolding: Especially prevalent in Hong Kong and parts of Southeast Asia, bamboo scaffolding is valued for its strength, flexibility, and eco-friendliness. It is commonly used for both low-rise and high-rise construction, including skyscrapers.

Steel and System Scaffolding: In rapidly urbanizing countries like China, Japan, and India, steel-based system scaffolding (such as cuplock, kwikstage, and Haki) is widely used for large-scale projects due to its strength, modularity, and compliance with modern safety standards.

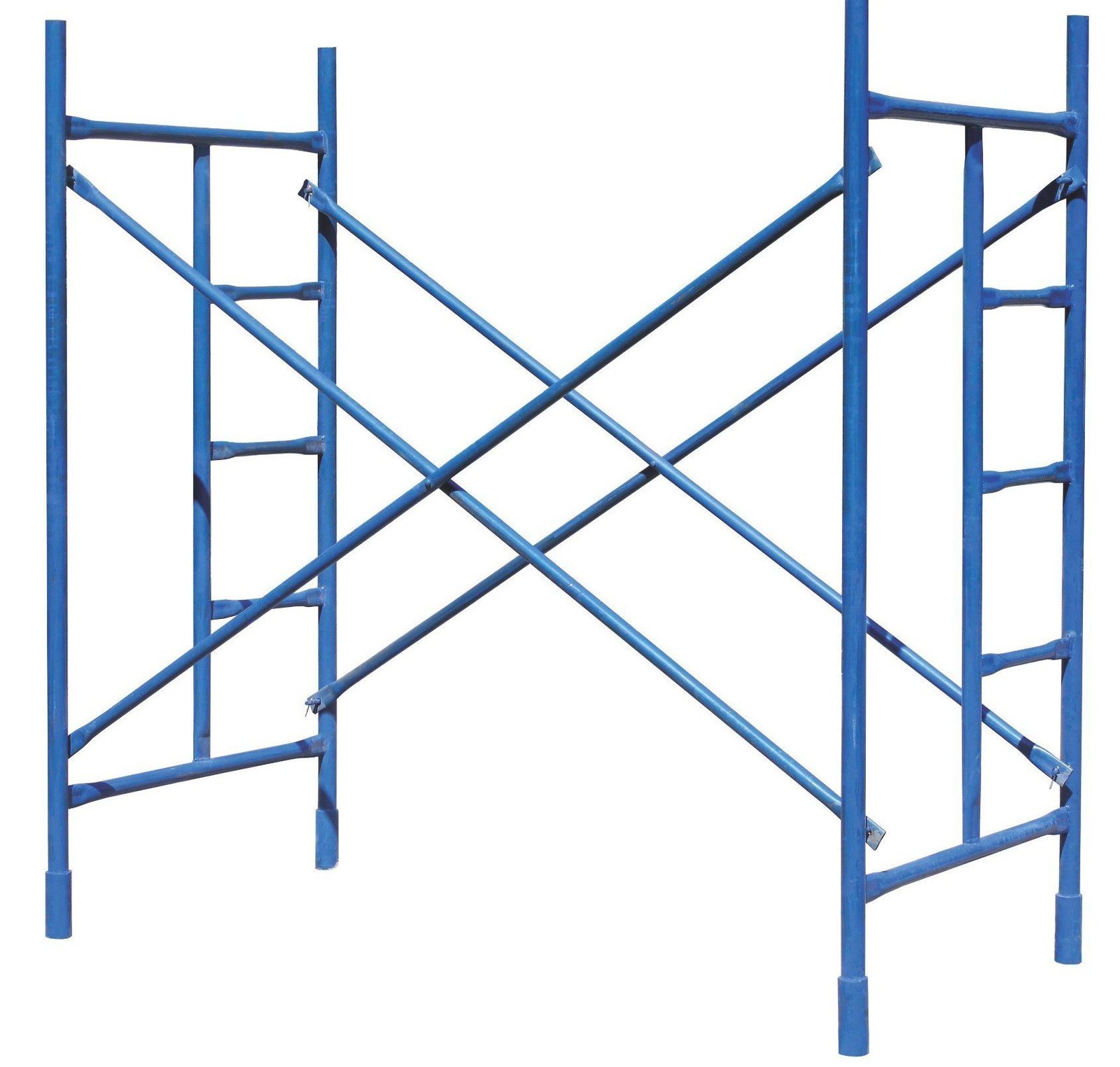

Frame and Modular Scaffolding: Increasingly common in Japan and urban centers for regulated maintenance and high-rise construction. Easy to use and assemble for quick works in small spaces. Available in various configurations.

Europe

Aluminium and Steel System Scaffolding: In Northern and Western Europe, labour costs are high, making lightweight aluminium scaffolding popular, especially in Scandinavia. Steel system scaffolding (such as cuplock and kwikstage) is also widespread for its durability and ease of assembly.

Frame and Brace Scaffolding: Common in residential and light commercial projects, especially in Southern and Eastern Europe.

Traditional Wooden Scaffolding: Still used in some restoration projects, though less common than modern systems.

North America

Frame Scaffolding:

The most recognized and widely used type in residential and light commercial construction due to its simplicity and speed of assembly.

System Scaffolding: Preferred for complex structures, large commercial sites, and industrial plants, offering flexibility and strength.

Supported and Suspended Scaffolding: Supported scaffolding is common for general construction, while suspended scaffolding is used for high-rise exterior work, especially in major cities.

West Asia & Africa

System Scaffolding (Cuplock): Highly popular due to its heavy-duty capabilities, ease of setup, and cost-effectiveness, especially in the UAE and other Gulf countries.

Steel and Modular Systems: Increasingly adopted for both commercial and infrastructure projects, driven by urbanization and large-scale development.

Influence of Labour Cost on Scaffolding Material Choice

High Labour Cost Regions (e.g., Western Europe, North America)

Preference for Modular and System Scaffolding: In regions with high labour costs, there is a strong incentive to use scaffolding systems that are quick and easy to assemble and dismantle, such as modular steel or aluminium systems. These systems reduce the number of labour hours required, offsetting higher wage rates and improving overall project efficiency.

Investment in Advanced Systems: Higher upfront material costs for modular or pre-engineered scaffolding are justified by significant labour savings over the project duration. This is especially relevant for large-scale or complex projects.

Low Labour Cost Regions (e.g., parts of Asia, Africa)

Use of Labour-Intensive Materials: In countries where labour is relatively inexpensive, traditional and labour-intensive scaffolding materials like bamboo (in Asia) or timber may still be widely used. These materials require more manual labour for assembly and disassembly, but the lower wage rates make this approach cost-effective.

Less Incentive for High-Efficiency Systems: The cost savings from labour-efficient modular systems are less pronounced, so contractors may opt for cheaper, locally available materials even if they require more labour input.

Middle-Income Regions (e.g., Eastern Europe, Latin America)

Mixed Approaches: These regions often balance material and labour costs, sometimes using modular systems for large or urban projects while relying on traditional methods for smaller or rural jobs.

Additional Regional Factors

Local Market Rates: Labour costs vary not just by country, but also within regions and cities, further influencing the choice of scaffolding systems.

Project Type and Duration: Projects requiring quick turnaround or those in high-wage urban centers are more likely to use advanced, labour-saving scaffolding systems.

Most Prevalent Scaffolding Standards

Construction Industry

United States: OSHA 29 CFR 1926 Subpart L is the primary standard, detailing requirements for load capacity, fall protection, guardrails, planking, inspections, and safe access.

Europe: EN 12810 / 12811 standards define system configurations, performance, and safety requirements for prefabricated scaffolding systems.

BS 1139, EN 74, and EN 39 are also widely referenced for materials and component compatibility.

Canada: CSA Z797-09 covers base plates, screw jacks, platform widths, and guardrail requirements.

Australia: AS/NZS 1576 is the key standard for scaffolding design, erection, and use, with recent updates emphasizing safer erection methods and anti-tamper devices.

International: ISO 9001 (quality management) and ISO 1461 (galvanized steel) ensure global quality and durability, especially in multinational projects.

Oil & Gas, Industrial, and Maintenance Sectors

Global: ISO standards (ISO 9001, ISO 1461) are often required for projects involving multinational contractors or high safety demands.

EN 12810/12811 and OSHA standards are frequently referenced, depending on project location and client requirements.

Key Elements Across Standards

Load Capacity: Scaffolds must support at least 4 times the required load.

Fall Protection: Guardrails, toe-boards, and personal fall arrest systems are mandatory above certain heights (typically 10 feet/3 meters).

Platform Requirements: Full planking, minimum width, and secure installation.

Inspection: Regular/daily inspections by a competent person.

Access: Safe access via ladders, stairs, or internal means.

Material Quality: Standards like ISO 1461 ensure corrosion resistance and durability for steel scaffolding.

Scaffolding Standards Used in India

India employs a set of national standards and regulations to ensure the safety and reliability of scaffolding in the construction and industrial sectors. The key standards and regulatory frameworks are as follows:

Bureau of Indian Standards (BIS) Codes

IS 3696 (Part 1): 1987 – Safety Code of Scaffolds and Ladders (Scaffolds)

Provides comprehensive safety requirements for the design, erection, use, and dismantling of scaffolds, including specifications for materials, dimensions, and construction practices.

IS 3696 (Part 2): 1991 – Safety Code for Ladders

Focuses on safety requirements for ladders used in construction, maintenance, and demolition activities.

IS 4014 (Parts 1 & 2): Code of Practice for Steel Tubular Scaffolding

Part 1: Definitions and materials.

Part 2: Safety provisions and best practices for steel tubular scaffolding.

IS 2750: 1964 – Specification for Steel Scaffoldings

Specifies requirements for materials, fabrication, and performance of steel scaffoldings, mainly for normal building construction work.

IS 4014 and IS 3696 are the most referenced for steel and general scaffolding safety, respectively.