Rotary Equipments In Petrochemical Sector

Rotary equipment in the petrochemical sector comprises machinery with rotating components that perform critical functions such as fluid movement, gas compression, power generation, and mechanical processing. These machines are essential for operations including refining, production, and transportation of petrochemical products. These machines are designed and maintained under stringent industry standards (e.g., API, ASME) to ensure safety, reliability, and performance.

Types of Rotary Equipment in the Petrochemical Sector

Pumps

They are used to move fluids (liquids and slurries) throughout the process. Common types include centrifugal pumps, which use impellers to increase fluid velocity, and positive displacement pumps, which deliver a fixed volume per rotation for precise flow control. Specialized pumps include dosing pumps for chemical injection, feed water pumps for boilers, and submersible pumps for underground fluid extraction.

Compressors

They are employed to compress gases, increasing their pressure for transportation or processing. There are of two main types:

Rotary compressors (e.g., screw compressors) that use interlocking rotors to compress gas.

Reciprocating compressors with piston-cylinder arrangements driven by external motors.

They are critical for gas handling in refining and petrochemical plants.

Turbines

They Convert fluid or steam energy into mechanical power, often used to drive generators or other equipment. Steam turbines are widely used to generate electricity on-site, especially where grid power is unavailable (e.g., offshore rigs).

Fans and Blowers

They facilitate air or gas movement for ventilation, cooling, or process requirements. They include axial and centrifugal types, designed to handle various flow rates and pressures.

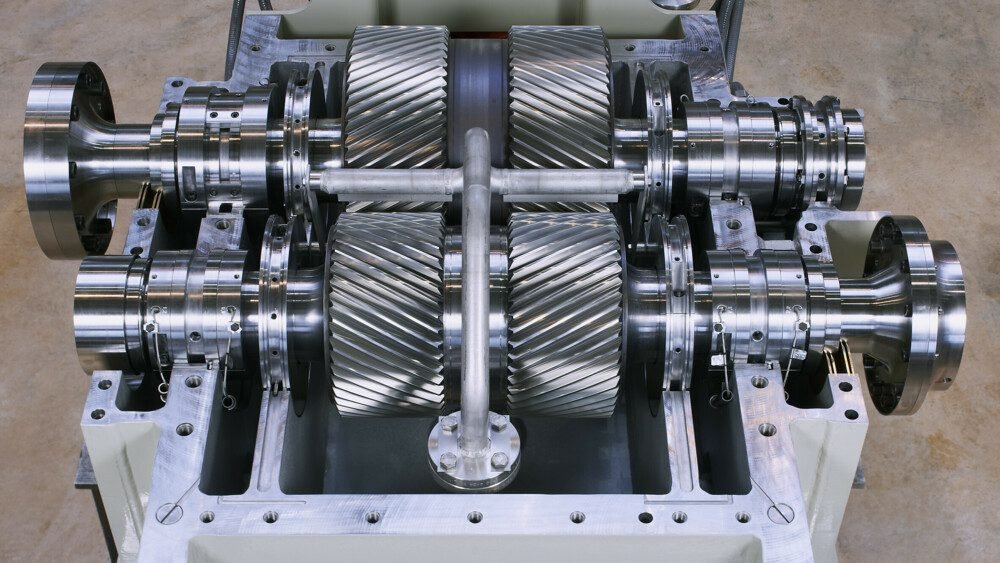

Gearboxes

They transmit power between rotating components, adjusting speed and torque as needed. Types include helical gearboxes (for high torque, low noise) and bevel gearboxes (for changing power transmission direction).

Electro Motors

They convert electrical energy into mechanical rotation to drive pumps, compressors, and other rotary equipment. Available in high-voltage and low-voltage variants depending on power requirements.

Agitators and Mixers

They are used for mixing fluids or slurries within reactors or storage tanks, ensuring uniformity in chemical processes. Agitators are ideal for tasks like keeping particles in suspension or maintaining a consistent temperature. Mixers excel in blending powders, emulsifying liquids, or creating smooth pastes

Key Maintenance Requirement

Regular Inspection and Condition Monitoring

Perform visual and dimensional inspections to detect wear, corrosion, or damage. Use condition monitoring techniques such as vibration analysis, temperature measurement, and acoustic monitoring to identify early signs of failure. Employ non-destructive testing (NDT) methods like magnetic particle inspection, ultrasound, and liquid penetrant inspection to detect hidden defects.

Lubrication and Seal Maintenance

Maintain proper lubrication schedules for bearings and gearboxes to reduce friction and wear. Inspect and replace mechanical seals and seal support systems regularly to prevent leaks, which are a major cause of downtime and safety risks in petrochemical plants.

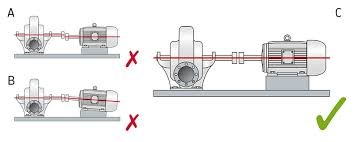

Alignment and Balancing

Conduct precise shaft alignment and rotor balancing to minimize vibrations, reduce mechanical stress, and extend equipment life. Regular alignment surveys are recommended to maintain optimal performance.

Scheduled Preventive and Predictive Maintenance

Implement time-based preventive maintenance such as lubrication, calibration checks, and housekeeping at regular intervals. Use predictive maintenance based on condition monitoring data to plan repairs before failures occur, improving reliability and reducing downtime.

Timely Repairs and Component Replacement

Inspect equipment during planned or unplanned outages to assess damage and determine repair or replacement needs. Replace worn or damaged parts like impellers, which may require advanced manufacturing techniques for improved efficiency and durability.

Safety and Documentation

Follow strict safety procedures and lockout-tagout protocols during maintenance activities. Maintain detailed records of maintenance activities, inspections, and repairs to track equipment health and optimize maintenance strategies.

Collaboration with Experienced Vendors

Work with local vendors experienced in petrochemical rotating equipment to ensure availability of spare parts and technical support, reducing maintenance response times and costs.

Most Effective Predictive Maintenance Techniques

The most effective predictive maintenance techniques for rotary equipment combine advanced condition monitoring methods with data analytics to anticipate failures and optimize maintenance schedules. Expert consensus and industry research consistently identify the following techniques as the most impactful:

Vibration Analysis

Vibration analysis is widely regarded as the most effective method for detecting defects in rotating machinery such as pumps, motors, turbines, and compressors. It detects Imbalance, misalignment, bearing faults, looseness, and gear defects. It this a sensor monitors vibration patterns (displacement, velocity, acceleration, frequency, phase angle). Changes in these parameters indicate developing faults. It is ranked highest by industry experts due to its ability to provide early warnings and detailed diagnostics.

Acoustic (Ultrasound) Analysis

Acoustic analysis uses ultrasonic sensors to detect high-frequency sounds produced by leaks, electrical discharges, and early-stage bearing failures. It detects Cracks, leaks, lubrication issues, and electrical faults. Continuous detection and analysis of sound patterns reveal anomalies not always picked up by vibration analysis.

Oil Analysis

Oil analysis examines lubricant samples for contamination, wear particles, and chemical composition. It detects bearing and gear wear, contamination, lubrication degradation. Regular sampling and laboratory analysis track viscosity, temperature, density, and presence of wear metals, providing insight into internal component health.

Infrared Thermography

Infrared (IR) thermography uses thermal imaging to detect abnormal heat patterns in equipment. It detects overheating due to friction, electrical faults, insulation breakdown, and misalignment. IR cameras visualize temperature differences, enabling early intervention before catastrophic failure.

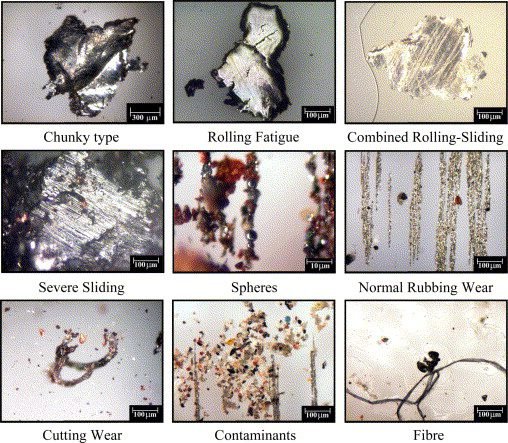

Wear Particle Analysis

Wear particle analysis focuses on identifying and quantifying metallic and non-metallic particles in lubricants. It detects component wear, fatigue, and impending failure. Microscopic and spectrometric analysis of oil samples to monitor the type and quantity of wear debris.

Data Analytics and Machine Learning

Advanced analytics and AI models process large volumes of condition monitoring data to predict failures and optimize maintenance timing. It detects anomalies and patterns not easily visible through manual analysis. Machine learning algorithms establish baseline performance, detect deviations, and estimate remaining useful life of components.