Refractory Installation Methods

A refractory material is an inorganic, non-metallic substance that can withstand extremely high temperatures—typically above 1,000 °F (538 °C)—without losing its strength, shape, or chemical integrity. These materials are resistant to decomposition by heat, chemical attack, and mechanical stress, making them essential for lining furnaces, kilns, reactors, incinerators, and other equipment exposed to harsh, high-temperature environments. Selection of the appropriate method depends on factors such as project size, location, refractory material type, required durability, installation speed, and the skill of the installation team. The main refractory installation methods are:

Casting (or Vibration Casting):

Wet refractory material is mixed and poured into forms or molds, sometimes with vibration to ensure compaction and remove air pockets. Vibration casting is especially used for low-cement castables to achieve a denser, stronger structure.

Pump Casting:

Similar to standard casting, but the refractory mix is pumped into place using specialized equipment. This method allows for faster and more efficient placement, especially in large or hard-to-reach areas.

Shotcrete:

A low-cement, low-moisture refractory mix is blended with water and additives, then sprayed at high velocity onto surfaces using a piston pump and compressed air. This method is ideal for applying refractory linings quickly, especially at high elevations or where access is difficult.

Gunite:

Dry refractory material is pneumatically conveyed through a hose and hydrated at the nozzle just before application. The material is then sprayed onto the surface at high speed. Gunite is often used for repairs or when access is limited and requires a skilled installation team.

Ramming:

Plastic or semi-plastic refractory material is hand-rammed or pneumatically hammered into place, often around anchors or fittings. This method is suitable for areas where forms cannot be used or for patching and repair work.

Bricklaying:

Although not a monolithic method, traditional refractory bricks are laid in place using refractory mortar. This remains common for certain furnace and kiln linings. Specialized brick layers are used to operate this brick laying machine.

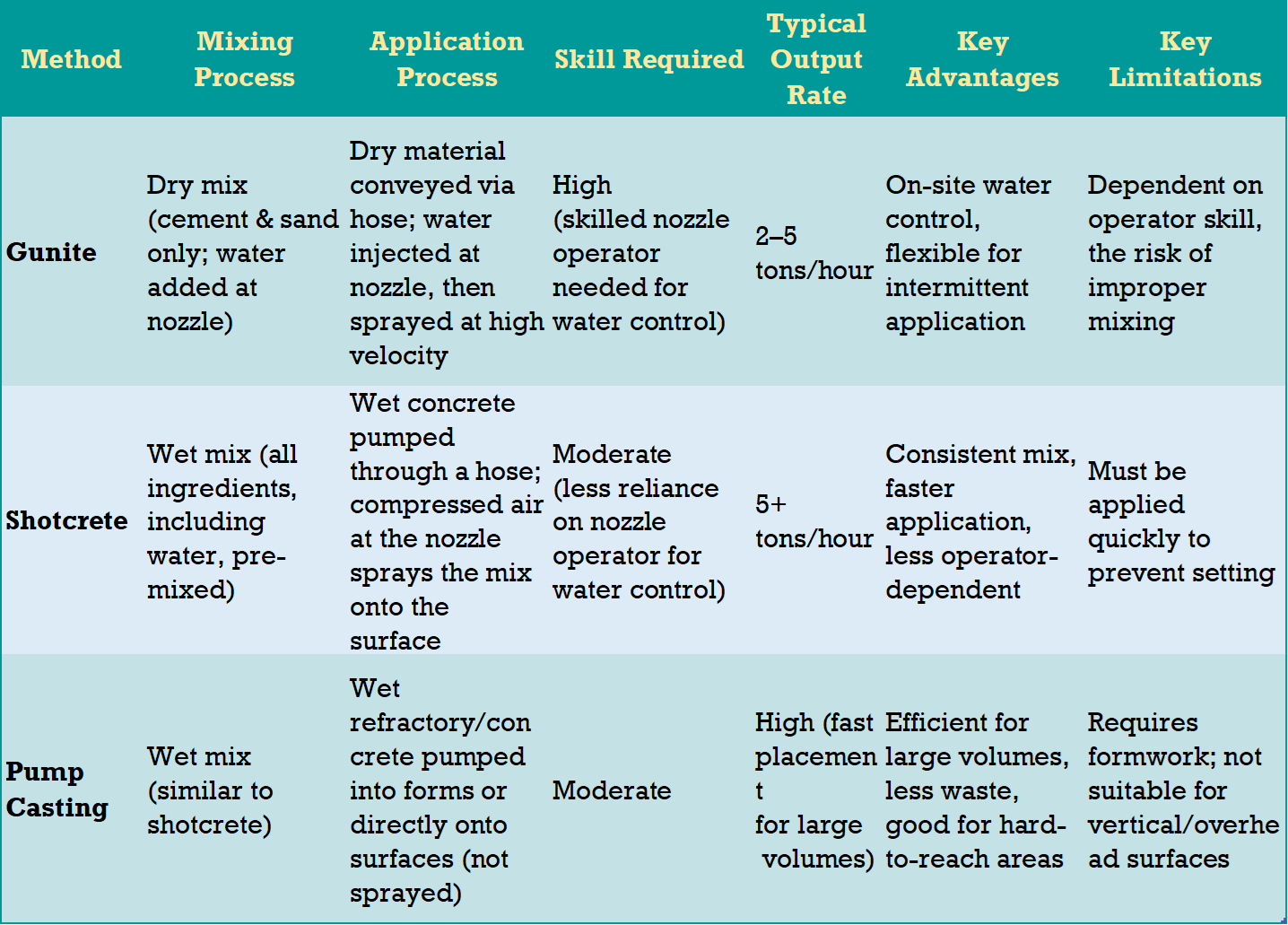

Refractory Installation Methods: Key Differences

Refractory Installation Equipments

Shotcrete: Its high application speed allows for rapid placement of refractory material, especially on large, vertical, or overhead surfaces. This speed can significantly shorten project timelines, enabling completion of large-scale linings or repairs in a fraction of the time required by slower methods. The consistency and reduced reliance on operator skill also minimize rework, further streamlining schedules.

Pump Casting: Also offers high volume capacity and fast placement when the project area is accessible and formwork is practical. For large, open, or formed surfaces, pump casting can match or exceed shotcrete’s speed, allowing for quick completion of bulk installations. However, setup time for forms and pump equipment can slightly offset the speed advantage for smaller or more complex jobs.

Gunite: Has a slower application rate (typically 2–5 tons/hour) and is more dependent on the skill of the nozzle operator for proper hydration and compaction. This results in longer project timelines for large areas compared to shotcrete or pump casting. Gunite is better suited for smaller repairs or intricate work, where the slower pace is less of a disadvantage.

Selection of Refractory Installation Method

Compatibility with Material Properties: Different installation methods are better suited to specific refractory materials. For example, casting works well with certain dense castables, while gunning is ideal for quick repairs. Using an incompatible method can result in poor bonding, gaps, or weak spots, reducing the lining’s durability.

Density and Integrity of Lining: Methods like shotcrete and casting can achieve high density and uniformity when performed correctly, which enhances resistance to thermal shock, chemical attack, and mechanical stress. Poorly executed methods, or those unsuited to the material or application, may leave voids or weak areas, making the lining more prone to premature failure.

Skill and Technique: The effectiveness of any installation method depends heavily on the skill of the crew. Incorrect mixing, application, or curing—regardless of method—can lead to cracks, poor adhesion, and reduced service life. For instance, both shotcrete and gunite require careful control of water content and application technique to ensure optimal compaction and bonding.

Curing and Drying: Some methods, such as casting, require longer and more controlled curing and drying processes. Incomplete or improper curing can compromise final strength and durability, making the lining susceptible to spalling or thermal shock.

Speed and Volume: High-speed methods, such as shotcrete and pump casting, can be advantageous for large projects but may also increase the risk of errors if not properly managed. Rapid application without adequate quality control can lead to uneven thickness or incomplete compaction, thereby reducing durability.

Site Conditions and Application Complexity: The chosen method must account for the geometry of the installation area, access limitations, and operating conditions. For example, gunning may be preferable for overhead or hard-to-reach areas, but may not achieve the same density as casting in open, accessible zones.