M.E.P in Refinery Projects

MEP (Mechanical, Electrical, and Plumbing) systems play a crucial role in ensuring the safe, efficient, and reliable operation of refinery construction projects due to their complex industrial requirements. They also include complex, high-pressure industrial gas distribution, emergency systems, and sophisticated control systems vital for safety, operational efficiency, and compliance with stringent industry standards.

Mechanical Systems in Refineries

Piping and HVAC:

Mechanical systems in refineries focus on designing and installing piping networks for the transport of crude oil, process fluids, steam, and other gases, as well as specialized HVAC units for safe ventilation and temperature control in hazardous environments.

Equipment Integration:

Mechanical engineers ensure that pumps, heat exchangers, compressors, and turbines are properly fitted and coordinated with other systems to achieve optimal performance and ensure operational safety.

Electrical Systems in Refineries

Power Distribution:

Refineries demand robust electrical infrastructure for high-voltage power supply, lighting, and process automation.

Instrumentation and Control:

Electrical engineers design control panels, motor control centers, and integrate sensors and instrumentation for process monitoring, automation, and safety interlocks. Electrical designs must meet strict standards to prevent fire and explosion risks in flammable atmospheres.

Plumbing Systems in Refineries

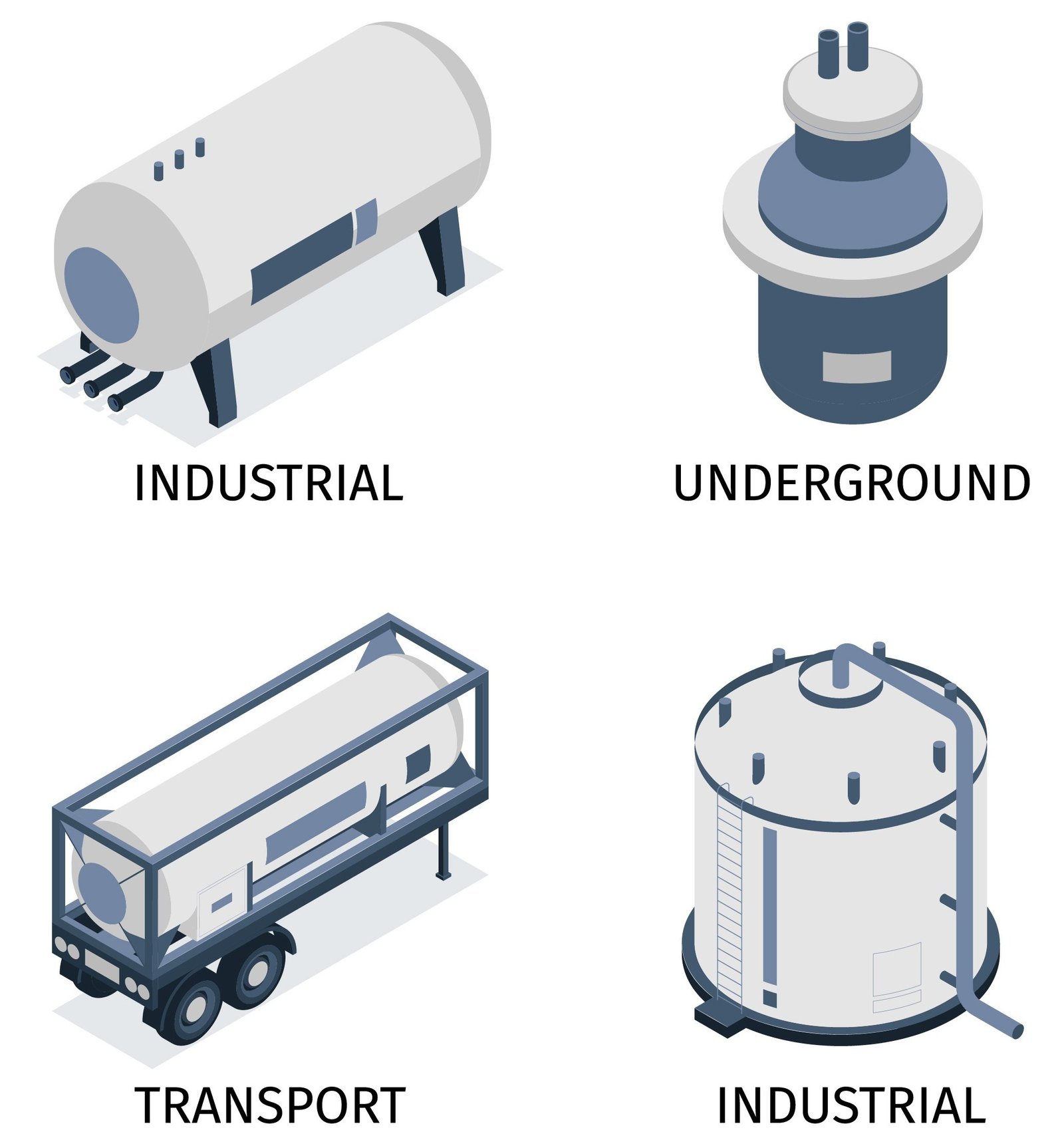

Industrial Piping:

Plumbing in refineries extends far beyond typical water and waste systems—designs include those for transporting process chemicals, utility water, fuel handling, compressed air, steam, waste disposal, and sometimes specialty gases.

Safety and Compliance:

Proper plumbing ensures safe containment and disposal of hazardous materials, adherence to environmental regulations, and seamless operation of fire suppression systems.

MEP teams verify that all systems work as intended through rigorous testing, functional validation, and documentation, ensuring compliance with regulatory requirements. Advanced control systems integrate MEP components for centralized monitoring, optimizing energy usage, safety, and operational reliability.

MEP Drawings

Mandatory MEP drawings for refinery IFC (Issued For Construction) packages include coordinated sets that cover mechanical, electrical, and plumbing systems, ensuring full compliance and constructability.

Mechanical/HVAC Drawings:

Show duct layouts, pipe routing, mechanical equipment arrangement, and specifications for heat, ventilation, temperature control, and process air systems.

Plumbing Drawings:

Detail piping configuration for potable/process water, wastewater, chemical transport, fire protection, and utility systems within the refinery.

Electrical Drawings:

Include power distribution plans, single-line diagrams (SLD), panel schedules, cable routing, grounding plans, lighting layouts, and hazardous area classifications.

Fire Protection Drawings:

Document placement and specifications of sprinklers, alarms, emergency exits, extinguishing systems, and integration with other safety features.

Coordination Drawings:

Integrate layouts for all MEP disciplines to resolve clashes, showing spatial relationships and sequencing for installation.

Penetration Drawings:

Identify where pipes, ducts, and cable trays intersect walls or slabs, ensuring no structural conflicts.

Detailed Shop Drawings:

Provide granular fabrication and installation instructions for piping spools, equipment supports, fixtures, and assemblies.

As-built Drawings:

Required after construction, these reflect the actual installed conditions for future maintenance.

Regulatory and Project Compliance

IFC packages must also include key schedules, legends, standard notes, and code compliance overlays (such as fire zones, pressurization, ADA routes) embedded directly on drawing sheets. Native CAD/BIM formats and versioned PDFs are mandatory for submission and construction teams. Every refinery IFC package must incorporate these drawings to ensure safe, code-compliant, and streamlined execution for complex industrial environments.

MEP Work Breakdown

The typical percentage breakdown for mechanical, civil, electrical, and other works in refinery construction projects varies. Still, industry data and tender documents suggest that mechanical and piping works constitute the largest portion, followed by civil works, then electrical and instrumentation works.

Mechanical (including piping and equipment):

This category typically accounts for the bulk of the cost and effort, often comprising around 40-50% of the total construction work in refinery projects.

Civil (structural, foundations, buildings):

Usually accounts for 25-35% of total construction activities.

Electrical (power distribution, lighting, cabling):

This typically accounts for 10-15% of the construction scope.

Instrumentation & Controls:

Typically, 5-10% of total works, sometimes grouped with electrical or listed separately.

Additional activities, such as underground utilities, fire protection, and other site development, may make up the remaining share, especially in large, complex refineries.

Refractory and insulation works in refinery construction typically account for a much smaller percentage compared to civil, mechanical, or electrical works, usually ranging between 2–5% of the total construction value. Refractory works involve the installation of heat-resistant materials in furnaces, reactors, and other high-temperature equipment, typically accounting for approximately 1–3% of the total construction costs for a refinery project.

Insulation works (thermal and acoustic insulation in pipes, vessels, and equipment) usually occupy 1–2% of the total scope. The combined share for refractory and insulation is most substantial in key process areas like furnaces, boilers, and reactors. Still, their scope is limited compared to piping, structural, or electrical works. This share may vary slightly based on refinery design, complexity of units, and specific environmental or operational needs.