Equipment Utilization in Maintenance Works

Equipment plays a central and multifaceted role in maintenance, influencing not only how maintenance is performed but also the effectiveness, safety, and efficiency of maintenance programs. Properly maintained equipment is crucial for minimizing unplanned downtime and operational disruptions, thereby preserving productivity and ensuring business continuity. Regular maintenance—such as inspections, lubrication, and part replacements—prevents excessive wear and tear, allowing equipment to operate effectively for longer periods. This extends the overall service life of assets and reduces the need for expensive replacements.

Well-maintained equipment functions more efficiently, consuming less energy and delivering consistent output quality. Maintenance helps keep equipment calibrated, clean, and operating at peak performance.

Proactive and scheduled maintenance is much less costly than emergency repairs or equipment replacement following a major breakdown. Proper maintenance practices minimize repair costs and optimize the return on investment from physical assets.

Regular maintenance reduces the risk of equipment failure that could cause accidents or injuries. Maintenance activities also ensure compliance with safety standards and regulatory requirements.

Types of Equipment Maintenance

Preventive Maintenance: Scheduled, routine checks and servicing are designed to prevent equipment failures before they occur.

Predictive Maintenance: Uses real-time data and monitoring (often via sensors/IoT technology) to anticipate failures and service needs.

Corrective (or Reactive) Maintenance: Repairs and restores equipment following unexpected faults or failures.

Neglecting proper equipment maintenance can lead to frequent breakdowns, greater inefficiency, higher costs, compromised safety, and even regulatory violations or production losses.

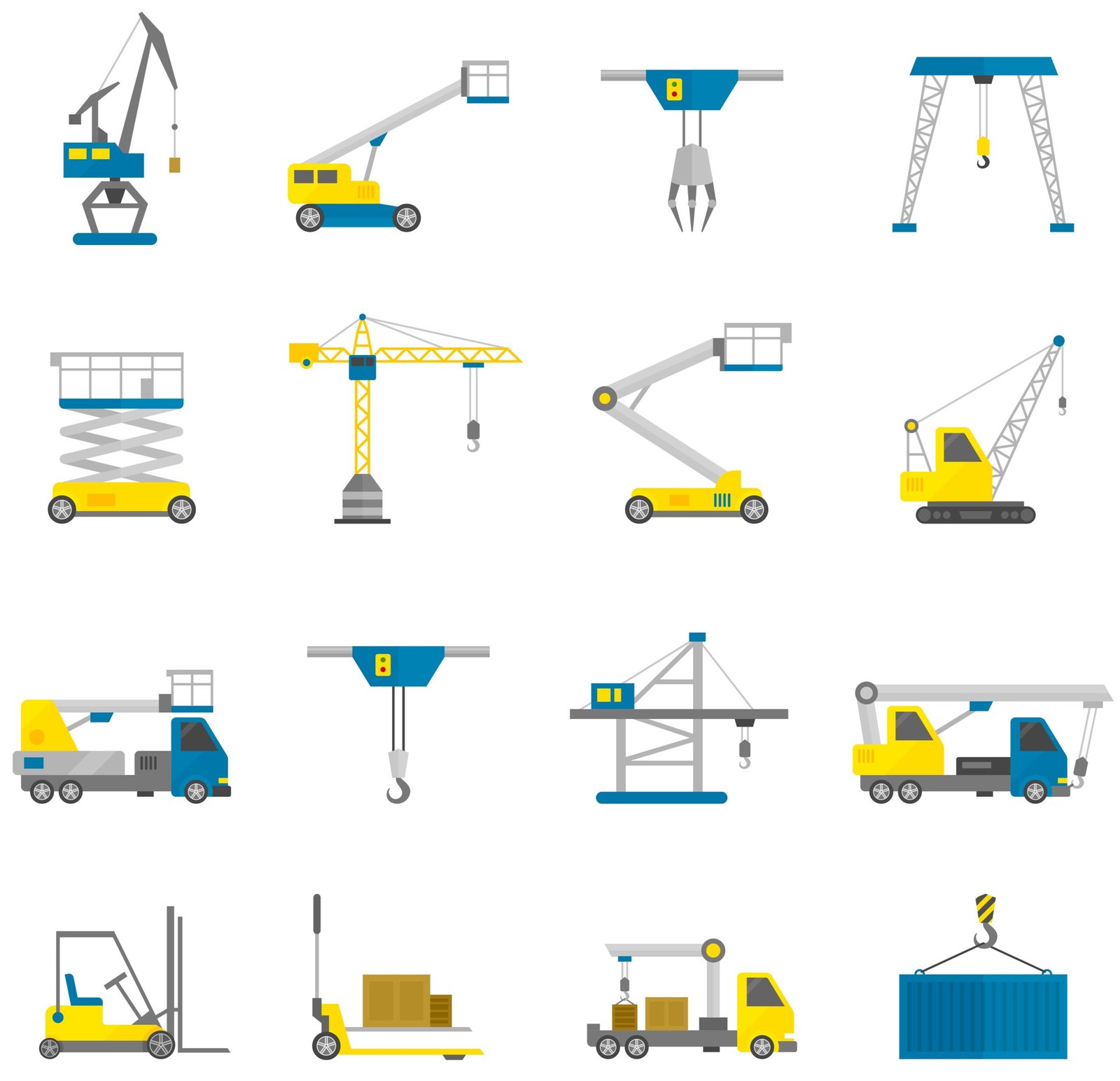

Heavy Equipment Used in Maintenance Works

Heavy equipment used during maintenance activities, especially in settings like oil & gas refineries, includes a wide range of powerful machinery designed to safely handle, lift, transport, or support heavy components and structures. The most common and critical types include:

Cranes: Lifting and placing heavy components such as pumps, heat exchangers, pressure vessels, and pipe spools during maintenance shutdowns or replacements. Ex: Mobile cranes, overhead cranes, truck-mounted cranes, jib cranes.

Forklifts and Telehandlers: Moving heavy parts, pallets, drums, and equipment within maintenance areas or warehouses.

Aerial Work Platforms (AWP) & Boom Lifts: Providing safe elevated access for maintenance personnel to reach high valves, pipe racks, instrumentation, or overhead structures. Ex: Scissor lifts, articulating boom lifts, and telescopic boom lifts.

Earthmoving Equipment: Excavating soil for repairs, removing old foundations, or repositioning buried pipelines and cables. Ex: Excavators, backhoes, front loaders, bulldozers (for site preparation, trenching, or ground repairs during maintenance shutdowns).

Skid Steer Loaders & Multi-terrain Loaders: Manoeuvring heavy materials in confined spaces, site cleanup, and debris removal after dismantling.

Utility and Transport Vehicles: Hauling debris, removing components, new equipment, tools, or materials to and from the maintenance site. Ex: Dump trucks, flatbed trucks, utility vehicles.

Specialized Equipment Utilization

Hydrovac trucks: For non-destructive soil removal during underground repairs.

Concrete pumps: For civil works, if concrete structures require repair or modification.

Compact/portable generators and lighting towers: Power supply and illumination for night or confined-space maintenance.

Support Tools & Attachments: Lifting, aligning, or securing heavy equipment parts during installation or dismantling. Ex: Hydraulic jacks, mechanical hoists, tow motors (forklifts/lift trucks), augers, quick couplers, rippers.

Equipment Cost Factors

The cost of equipment used in refinery maintenance is driven by a variety of technical, operational, and management considerations. The following are the main factors that influence these costs:

Type and Quality of Equipment: Major equipment such as heat exchangers, pumps, compressors, reactors, and specialized tools (e.g., hydrotest pumps, tube bundle pullers) represent a significant cost component. Premium-grade materials (like industrial-grade stainless steel and heat-resistant parts) increase upfront costs but extend operational life and reduce long-term maintenance costs. Advanced equipment with features for energy efficiency, automated monitoring, and optimized operation tends to have higher initial costs but yields operational savings.

Maintenance Frequency and Requirements: Scheduled maintenance, preventive maintenance programs, and operational history of equipment impact ongoing costs. High-quality equipment often requires less frequent but more specialized maintenance, reducing the total cost of ownership. Consumable materials, spare parts, and specialized maintenance expertise are continuous costs that fluctuate with process type and operational practices.

Equipment Installation and Commissioning: Professional installation by qualified specialists is essential, usually adding 5–10% to equipment costs, but ensures correct configuration and safety. Installation calls for additional tools and equipment, which may result in unplanned costs.

Supplier Reputation and Service: Established manufacturers charge premium prices for proven reliability, better after-sales service, faster response to maintenance needs, and comprehensive warranties. Ease of obtaining spare parts and support plays a major role in long-term maintenance costs.

Other Notable Factors

Supporting and Ancillary Systems: Safety systems (such as air breathing compressors, ventilation fans, and fire protection) add to the overall cost. Regulatory compliance (ventilation, waste disposal, and monitoring systems) and supporting infrastructure must be budgeted along with the main equipment.

Manpower & Logistics: Labor for fitters, welders, machinists, supervisors, and inspection technicians is a substantial part of maintenance cost inputs, especially for specialized procedures. Equipment to transport and handle heavy machinery, such as trailers, cranes, and forklifts, is integral to maintenance and repair work.

Testing, Inspection, and Certification: Non-destructive testing (NDT), such as radiography, eddy current testing, and hydrotesting, is required for various maintenance tasks and adds to costs.

Energy Efficiency & Operational Optimization: Equipment with higher energy efficiency can bring significant long-term savings. Assessing cost-versus-performance via detailed cost-benefit analysis is key to optimizing both initial and ongoing costs.