Health Safety Environment (H.S.E) Works

HSE (Health, Safety, and Environment) requirements during a refinery shutdown are comprehensive and closely regulated, focusing on protecting human health, ensuring worker safety, and minimizing environmental risk.

Essential H.S.E Requirements

Work Permit Systems: No maintenance or intervention can begin without a valid work permit (e.g., for hot work, confined space entry, electrical isolation). Permits must be thoroughly cross-checked, and all isolation/energy control steps verified before work starts.

Hazard Identification and Risk Assessment: Conduct detailed pre-shutdown risk assessments (Job Safety Analysis, HAZOP) to identify physical, mechanical, chemical, and health hazards, including those associated with hazardous materials like H2S, hydrocarbons, asbestos, and catalysts.

Personal Protective Equipment (PPE): All staff must use relevant PPE (such as fire-resistant clothing, respiratory protection, hearing protection, safety shoes, gloves, eye protection) based on job-specific hazards.

Safe Work Practices and Supervision: Strict controls on access to operational units, use of correct tools and equipment, proper scaffolding with “FIT FOR USE” tags, and dedicated safety supervision.

Occupational Hygiene and Exposure Monitoring: Implement ongoing occupational hygiene monitoring (airborne contaminants, noise, thermal stress) and ensure health surveillance of workers, especially when dealing with hazardous materials.

Training and Safety Briefings: Regular mandatory safety inductions and job-specific training for all workers and contractors, including daily toolbox talks, emergency procedures, and drills.

Relevant H.S.E Requirements

Process Isolation and Decontamination: Complete depressurization, isolation (blinding), decontamination of vessels/equipment, and gas testing before any mechanical intervention.

Emergency Preparedness and Response: Well-documented, rehearsed emergency shutdown and evacuation procedures, assigned responsibilities, regular emergency drills, and robust incident response protocols.

Environmental Controls: Measures for safe disposal of hazardous waste (e.g., pyrophoric iron), spill control, minimizing emissions during draining/cleaning, and ensuring regulatory compliance at all times.

Housekeeping and Access Control: Continuous housekeeping to keep areas clear of flammable materials, scrap, cables, and to ensure safe vehicle and personnel movement, especially as shutdowns tend to be congested with workers and materials.

Health Monitoring and Medical Support: On-site medical resources, mandatory fitness checks, and rapid response capacity in the event of accidents, exposure, or medical emergencies.

These requirements are based on guidelines from authorities such as OSHA, national regulators, and international best practices. Failure to adhere to HSE protocols during refinery shutdowns dramatically increases the risk of injury, environmental contamination, and plant damage.

Personal Protective Equipment in H.S.E Works

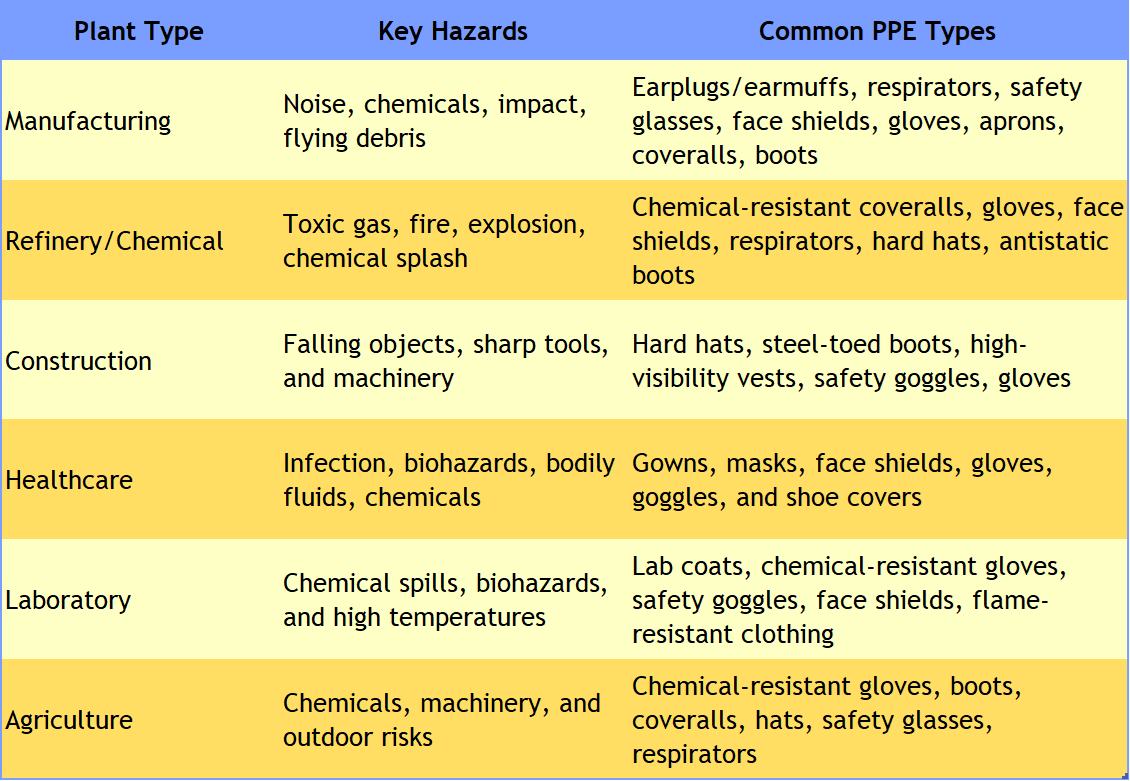

Different types of plants—such as refineries, manufacturing, construction, healthcare, laboratories, and agriculture—require specific types of Personal Protective Equipment (PPE) tailored to their unique hazards. The most common categories of PPE and their plant-specific applications are outlined below:

Head protection: Hard hats and bump caps for impact or overhead risks.

Eye/face protection: Safety glasses, goggles, and face shields against flying debris, splashes, or intense light.

Hearing protection: Earplugs or earmuffs for high-noise environments.

Respiratory protection: Masks, half/full-face respirators for dust, fumes, or toxic gases.

Body protection: Coveralls, aprons, lab coats, fire-resistant or HAZMAT suits.

Hand protection: Cut-resistant, chemical-resistant, or insulated gloves.

Foot protection: Steel-toed or chemical-resistant boots for impacts or hazardous spills.

Fall protection: Harnesses and lanyards for work at height, especially in construction and maintenance.

Selection of PPE always depends on task-specific risk assessment, ensuring it matches the hazards present in each plant type. Regular inspection and training on proper PPE use are essential for maximizing protection.

Safety Officer in H.S.E Works

During shutdown maintenance in refineries, the distribution of safety officers is structured to ensure comprehensive oversight across all high-risk activities and zones. The deployment is based on the complexity, size, duration, and risk profile of the shutdown, with the following general principles observed:

Central Coordination: A Shutdown HSE Manager leads the safety function for the entire shutdown. This person is responsible for the overall safety strategy, procedures, and compliance monitoring. A team of site safety officers supports them.

Shift Coverage: The nature of shutdowns—often running 24/7—requires that safety officers be present for each shift, with shift handover briefings and records to maintain continuity of oversight.

Area-Based Allocation: Safety officers are typically distributed by work area or unit—for example, one or more officers per process unit, utilities block, or offsite area, depending on the number and risk of simultaneous operations. High-hazard or congested zones (e.g., confined spaces, hot work areas, working at heights) receive a higher presence of safety officers.

Functional Oversight: Some officers are assigned to specific functions, such as:

- Permit-to-work compliance

- Gas testing and atmospheric monitoring

- Contractor and subcontractor management

- Confined space entry and rescue readiness

- Scaffolding, lifting operations, or fire water

Dynamic Adjustment: During shutdown peaks or critical operations, safety staff deployment is increased in areas where the most hazardous tasks are being performed.

Integration with Supervision: Safety officers work closely with area supervisors, shutdown coordinators, and contractor safety representatives to conduct joint walkthroughs, inspections, and daily toolbox talks.

Minimum Ratio: While no universal number exists, industry practice may range from one safety officer per 50–100 workers, adjusted for risk and by regulatory requirements. Major shutdowns with thousands of workers may have safety teams of several dozen officers.

Certifications Required in H.S.E Works

NEBOSH (National Examination Board in Occupational Safety and Health): The most widely recognized international certification, with key courses like the NEBOSH International General Certificate, NEBOSH International Diploma, and specialized sector certificates such as the NEBOSH International Technical Certificate in Oil and Gas Operational Safety.

IOSH (Institution of Occupational Safety and Health): Recognized mainly in the UK and Commonwealth countries, the IOSH Managing Safely certificate is a popular requirement.

OSHA (Occupational Safety and Health Administration): In the United States, OSHA has a range of certifications for safety professionals relevant to general industry, construction, and process industries.