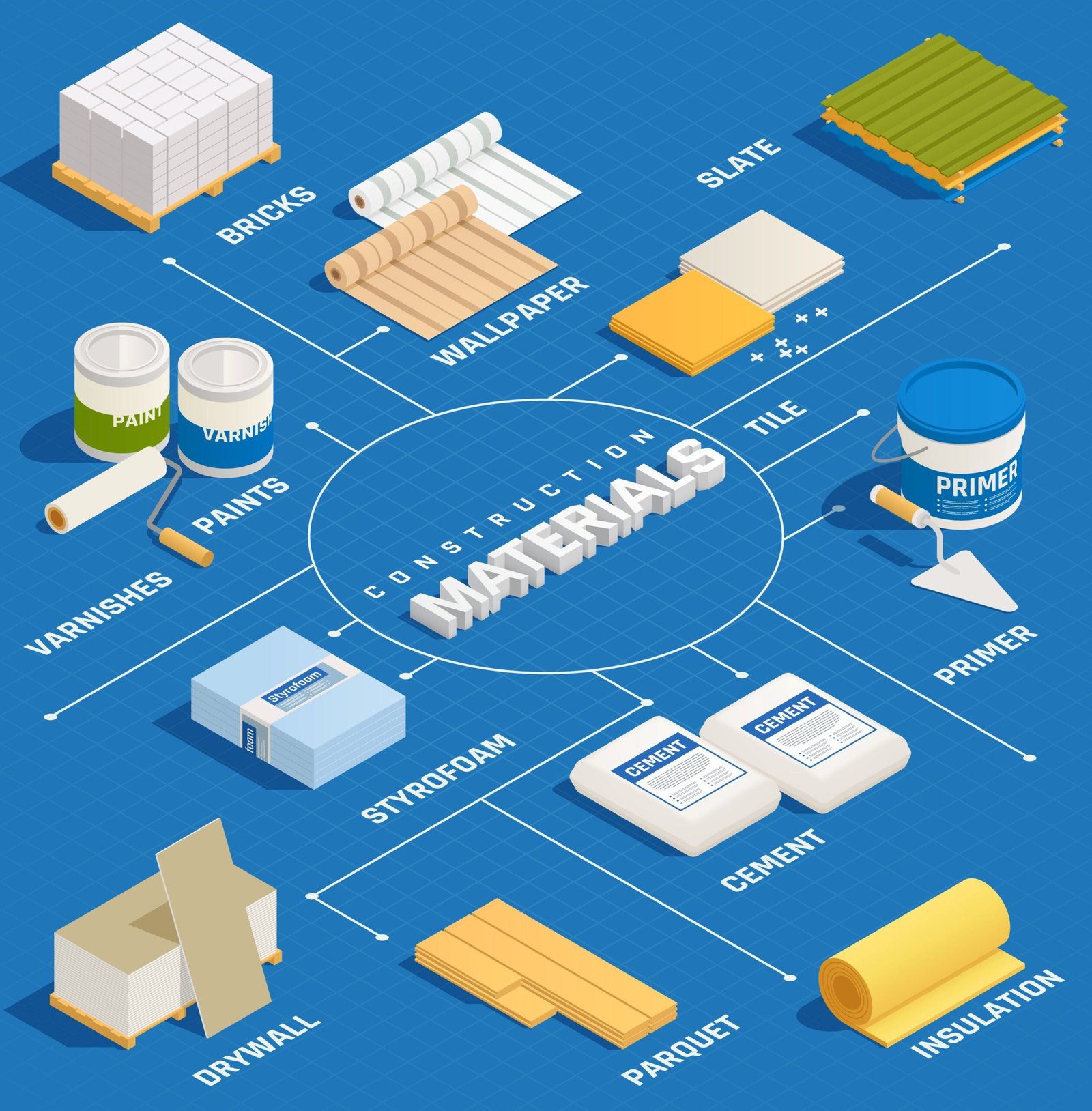

Insulation Materials in Oil & Gas Sector

Insulation materials are substances specifically designed to reduce or resist the transfer of heat, electricity, or sound from one side to another. Insulation materials in Oil & Gas sector (& other industries) are primarily used to maintain stable process temperatures by slowing down unwanted heat transfer through conduction, convection, or radiation. Key characteristics and properties of insulation materials include:

- Low thermal conductivity, meaning they do not easily allow heat to pass through.

- High electrical resistance, making them poor conductors of electricity (electrical insulators).

- Mechanical strength, to withstand physical stresses in industrial applications.

- Chemical and fire resistance, critical for safety and longevity in harsh environments.

- High dielectric strength, important in electrical applications to resist electrical breakdown.

- Resistance to moisture and contaminants, to maintain performance and prevent degradation.

Types of Insulation Materials

Mineral Wool (Rock Wool or Slag Wool):

Highly prevalent in refinery settings, this material offers excellent thermal insulation, fire resistance, and sound attenuation. It is frequently used for piping, vessels, and equipment subject to high temperatures.

Calcium Silicate:

This rigid insulation is often used on high-temperature pipe and equipment due to its high compressive strength, durability, and ability to withstand sustained heat.

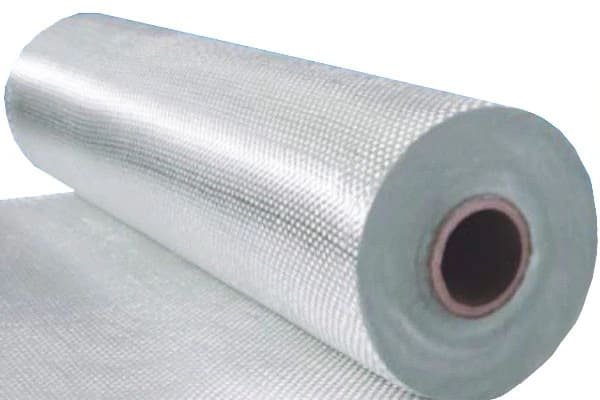

Fiberglass:

Widely used for both hot and cold service insulation, fiberglass is valued for its cost-effectiveness, ease of application, and moderate-to-high temperature performance, especially when properly jacketed for protection.

Foam Glass:

This rigid, closed-cell insulation is highly resistant to moisture and chemicals, making it suitable for piping and equipment that need protection from corrosion under insulation (CUI), especially in cold or cryogenic service.

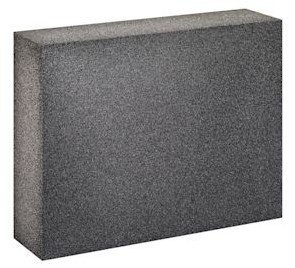

Polyisocyanurate and Polyurethane Foams:

Used primarily for colder temperature applications, including tank and pipe insulation in refrigeration systems and cold process areas. Polyisocyanurate offers better fire performance than polyurethane.

Perlite: Used predominantly for high-temperature systems such as vessels, tanks, and some piping, perlite performs well in harsh and high-temperature environments. It is also used in refractories due to its excellent insulating properties, primarily in high-temperature applications.

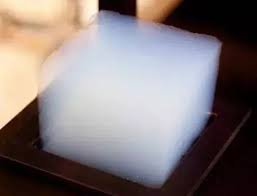

Aerogel:

This advanced insulation is occasionally used in refineries where extremely high-performance thermal insulation is required in minimal thicknesses. It is lightweight, hydrophobic, and offers very high thermal resistance.

Key factors influencing insulation material choice in refineries include operating temperature, fire safety needs, moisture resistance, mechanical durability, cost, and specific process requirements. Many refinery components, such as pipes, tanks, and ducts, are insulated with combinations of these materials to optimize safety and energy efficiency. Asbestos, once common in refineries, is now banned due to health risks. Proper installation and jacketing (often with metal sheeting) are essential to prevent issues like corrosion and maintain insulation integrity.

Insulation Material Maintenance

Maintenance of insulation material during a refinery shutdown should follow a structured approach to maximize equipment lifespan, operational safety, and energy efficiency. The process involves several key steps:

Pre-shutdown Planning

A detailed maintenance checklist is developed, identifying all insulation-covered equipment and prioritizing inspection areas based on process criticality and prior history. Clear objectives and timelines are to be set months in advance.

Inspection and Condition Assessment

During the shutdown, thoroughly inspect all insulation for physical damage (cracks, compression, delamination), moisture ingress, corrosion under insulation (CUI), and signs of chemical or thermal degradation. Pay special attention to vulnerable areas such as pipe elbows, flanges, equipment nozzles, and expansion joints.

Repair or Replacement

Remove insulation where moisture damage or CUI is suspected. Replace damaged insulation and vapor barriers. Use new materials that comply with process requirements, ensuring proper installation and jacketing to withstand refinery environments.

Cleaning and Surface Preparation

Clean and prepare surfaces before reapplying insulation, especially in areas affected by CUI. Apply corrosion protection coatings as required.

Documentation and Quality Assurance

Record the location, material type, and installed thickness of all new or repaired insulation. Conduct quality checks before closing out work fronts.

Re-inspection before Startup

Verify all insulation is intact, properly sealed, and securely jacketed before restarting equipment. Ensure that penetrations and protrusions are weather-tight.

Safety and Environmental Precautions

Implement all necessary safety protocols, provide appropriate PPE, and mitigate risks from handling fibrous or particulate insulation. Dispose of removed materials, especially if contaminated. Dispose of as per environmental and regulatory requirements.

Post-shutdown Review

Conduct debrief meetings to assess what worked and identify areas for improvement for future shutdowns.

These best practices help ensure insulation performance in refineries, minimizing energy losses and preventing corrosion and safety issues. Proper planning and execution are critical for reducing downtime and extending the insulation and equipment lifespan.

Insulation Material Manufacturers

Rockwool A/S (Denmark):

A global leader in stone wool and mineral wool insulation, widely used for fire resistance and energy efficiency in high-temperature oil & gas applications.

Saint-Gobain Isover (France):

Provides a wide range of technical insulation solutions, including stone wool and glass wool, catering to industrial and cryogenic applications in oil & gas environments.

Knauf Insulation (Germany/US):

Offers glass wool, stone wool, EPS, and other insulation materials for industrial, technical, and OEM applications.

Cabot Corporation (US):

Specializes in high-performance aerogel insulation, valued for its thin profile where space and weight are critical.

Owens Corning

(US):

One of North America’s largest producers of fiberglass and foam insulation for industrial pipelines and equipment.

Insulcon B.V. (Netherlands):

Focuses on high-temperature insulation and refractory products for the petrochemical and oil & gas sectors.