Refractory Materials and Leading Vendors

Refractory materials are heat-resistant materials used to line furnaces, kilns, reactors, and other high-temperature processing units. A typical refractory material is primarily composed of oxides, carbides, or nitrides of elements such as silicon, aluminium, magnesium, calcium, boron, chromium, and zirconium.

The most common oxides used in refractory materials are alumina (Al₂O₃), silica (SiO₂), magnesia (MgO), and lime (CaO). They are classified based on chemical composition, physical form, and application.

Types of Refractories and Their Uses

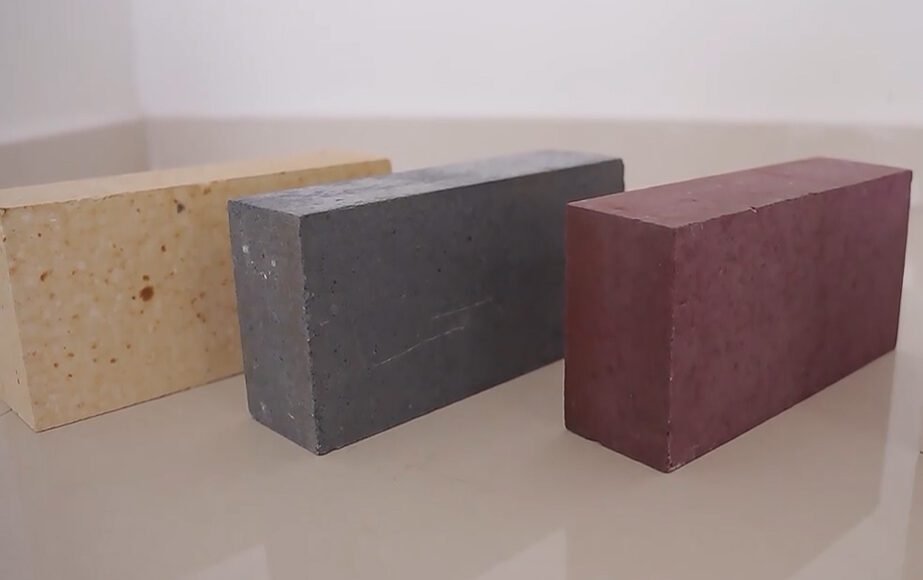

Fireclay Refractories

Composition: Hydrated aluminium silicates with 25-45% Al2O3 and 50-80% SiO2.

Characteristics: Inexpensive, widely available, good thermal stability.

Uses: Lining regenerators, furnaces, kilns, and stoves in industries like steel and cement.

Leading Vendors: TRL Krosaki Refractories (India/Japan), Saint-Gobain (France), Harbison Walker International (USA) etc.

Notes: TRL Krosaki is a major player in India with a broad product range; Saint-Gobain and Harbison Walker offer diverse fireclay and general refractory products globally.

Silica Bricks

Composition: Around 93% SiO2.

Characteristics: High mechanical strength near the fusion point and resistant to acidic slags.

Uses: Glass industry, steel industry, and high-temperature furnace walls.

Leading Vendors: Saint-Gobain, AGC Group (Japan), Kyocera (Japan) etc.

Notes: These companies have strong ceramic and silica-based refractory portfolios.

High Alumina Refractories

Composition: 45-95% alumina (Al2O3), including sillimanite, mullite, and corundum forms.

Characteristics: High refractoriness and good resistance to chemical attack.

Uses: Blast furnace hearths and shafts, lime and ceramic kilns, cement kilns, glass tanks, and crucibles.

Leading Vendors: CUMI Super Refractories (India), Vesuvius (UK), Morgan Advanced Materials (UK), RHI Magnesita (Global) etc.

Notes: CUMI leads in specialty high alumina refractories; Vesuvius and Morgan provide advanced alumina-based solutions worldwide.

Basic Refractories

Composition: Magnesite (MgO), dolomite (CaMg(CO3)2), and magnesia-chrome (MgO + Cr2O3).

Characteristics: Stable against basic slags, high refractoriness, corrosion and abrasion resistance.

Uses: Metallurgical furnaces, converter and refining furnaces, glass tank checks, lime and cement kilns.

Leading Vendors: RHI Magnesita (Global), Vesuvius (UK), Calderys (Global) etc.

Notes: RHI Magnesita is a world leader in basic refractories; Vesuvius and Calderys also have extensive offerings for the steel and cement industries.

Neutral Refractories

Materials: Alumina (Al2O3), chromia (Cr2O3), carbon graphite.

Characteristics: Chemically stable in both acidic and basic environments.

Uses: Highly reducing environments, steelmaking furnaces, crucibles, and moulds.

Leading Vendors: Morgan Advanced Materials, Showa Denko K.K. (Japan), Saint-Gobain etc.

Notes: Morgan and Showa Denko specialize in high-performance neutral refractories for steel and metallurgical applications.

Plastic Refractories

Composition: Refractory materials mixed with binders and plasticizers.

Characteristics: Good plasticity, shapeless, can be rammed or shaped.

Uses: Industrial furnace linings, soaking furnaces, annealing furnaces, sintering furnaces.

Leading Vendors: Harbison Walker International, IFGL Refractories (India), Saint-Gobain, Calderys (Global) etc.

Notes: Harbison-Walker and IFGL provide plastic refractories with strong thermal shock resistance; Saint-Gobain offers customized solutions.

Casting Materials

Composition: Mixture of aggregates, powder, cement, and admixtures.

Characteristics: Good fluidity for pouring moulds.

Uses: Various industrial furnaces, monolithic refractory linings.

Leading Vendors: Calderys, Harbison Walker International, Morgan Advanced Materials, Gouda Refractories etc.

Notes: Various Leaders in castable refractories suited for complex industrial furnace linings are available region wise.

Ramming Materials

Composition: Bulk refractory materials mixed with binders and additives.

Characteristics: Ramming-type refractory materials are primarily composed of granular and powdery refractory aggregates with a relatively low proportion of binders or additives like water glass, phosphoric acid, phosphate, aluminum sulfate, brine, or high alumina cement

Uses: Overall lining of open-hearth furnace bottoms, electric furnace bottoms, induction furnace linings, ladle linings, and tapping troughs.

Leading Vendors: RHI Magnesita, Vesuvius, TRL Krosaki Refractories, Resco USA etc.

Notes: These companies supply high-quality ramming mixes for furnace linings globally.

Chromite Refractories

Composition: Chromite mineral mixed with binders.

Characteristics: High refractoriness, resistance to slag corrosion.

Uses: Steel industry, lining open hearths, soaking pits.

Leading Vendors: Krosaki Harima Corporation (Japan), Shinagawa Refractories (Japan), Vesuvius etc.

Notes: Japanese companies like Krosaki and Shinagawa are known for chromite refractories; Vesuvius serves global steel markets.

Clay Bricks

Composition: Aluminium silicate materials with 30-48% Al2O3.

Characteristics: Clay bricks have high compressive strength, making them capable of withstanding significant loads.

Uses: Glass kilns, rotary kilns, general furnace linings, and building construction.

Leading Vendors: Rath AG, Merkel GmbH, K Hoffman GmbH, RS Refractory (China) etc.

Notes: RS Refractory (China) is one of the most prominent manufacturers, offering a full range of refractory clay bricks with high alumina content, excellent thermal resistance, and widespread global exports.

Special Refractories

Designed for extreme conditions like chemical corrosion, high temperature, and mechanical abrasion.

Characteristics: Pre-formed refractory products made in non-standard, customized shapes tailored to specific industrial applications.

Uses: Specialized industrial applications requiring enhanced properties.

Leading Vendors: Morgan Thermal Ceramics, Harbison Walker International, Saint-Gobain etc.

Monolithic Refractories

Composition: Granular, powdery raw materials with binders, no firing required.

Characteristics: Superior thermal properties and ease of installation.

Uses: High-temperature furnace linings, repair works

Leading Vendors: RHI Magnesita, Calderys, Harbison Walker International, Resco USA etc.

Notes: These firms dominate the monolithic refractory market with advanced formulations for diverse industries.